We purchae 28 bundles of rough sawn boards at a time.

Coming from the Gaspé region, the raw material is delivered by a bi-train truck.

The board are stickered in preparation for drying.

We have opted for a slow drying processes

that is based on ambient temperature, ventilation and time.

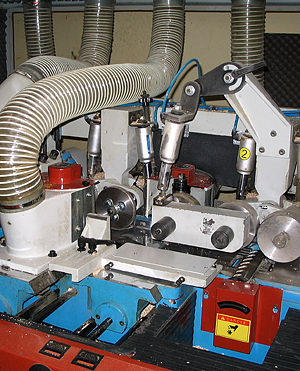

Transforming the drieds boards into finished products is done on modern, efficient machines

according to the most stringent specifications. Multiple resaws, moulders, planers,

wide belt sanding machines as well as complete finger-jointing line constitute the heart of

our remanufacturing equipment. Other more traditional machines serve to

fulfill small, custom-made orders.

A special feature to be mentioned is the fact that we do all the sharpening of high speed knives

and carbide plates in house. What a joy to have your cutting tools always in top shape.

|

|||

|

|

|||

|

|

|||

|

|||

|

|

|||

The team  The team  |

|||

|

|

|||